The essential bending style and design pointers that a designer requires to think about when modelling a sheet metal ingredient contain wall thickness, bend radii, and bend allowance.

The overall duration of your flat area slightly decreases following the functions because the bent part stretches some product. In this article, you have to deduct some size to get the complete flat duration, referred to as bend deduction.

The die is a hollow material the metal is put on leading of just before bending. It is a really tough and powerful substance that may be near in kind to the specified form from the metal becoming bent.

Though hydraulic press brakes continue to be probably the most commonplace due to their versatility, other forms have gained traction for precise production needs.

The orientation and form of these grains may be distinctive for every product style and way of forming like forging, casting, etc.

When specifying a press brake, it’s crucial to equilibrium the essential bending capacity and size with functional issues including manufacturing facility flooring energy, accessibility, and opportunity future relocation requires.

In the metalworking market, a press brake is a sophisticated machine tool engineered specifically for bending sheet and plate supplies, with sheet metal getting the predominant medium.

Y Axis: This axis governs the vertical motion of your upper beam (ram). Given that the ram descends or ascends, it specifically influences the bend angle. Over Discover the bending process, it’s important for that operator to be sure alignment concerning the Y1 and Y2 axes (still left and correct cylinders from the ram).

When choosing a goniometer for press brake apps, things such as measurement assortment, resolution, and magnetic energy must be considered to be certain compatibility with the precise bending duties and working environment.

One more comparable thought is corner reduction; it's the duration that should be cut out on the Conference position with the bent line. So, for the corners, you have to take into consideration a Lower-out for his or her best alignment and prevent substance tearing.

The directional conventions with the X, Y, and Z axes are illustrated by good arrows within the accompanying determine.

Have you ever at any time questioned how a press brake shapes metal with these precision? This text unveils the intriguing components and capabilities of the press brake, displaying you its vital part…

NC press brakes make the most of a pc to control the actions and capabilities of your machine in accordance with a selected, pre-programmed Doing the job sequence. This integration permits hugely correct and repeatable bending operations, very important in sheet metal fabrication.

These Handle units are typically mounted at a single stop on the press brake and serve as the main interface for programming and operating the whole system.

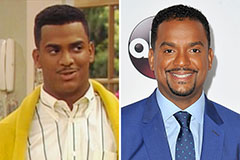

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Brooke Shields Then & Now!

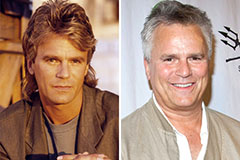

Brooke Shields Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!